Designing a Profitable Customer-Centric Electrification Solution

Customer- or user-centricity is nothing new. It's essential for almost all products and services and critical for acquiring and retaining customers. However, most large-scale electrification solutions (e.g., in the industrial sector) aren’t designed with the operator and end-user in mind.

Many manufacturers still get business despite the poor user experience simply because there are no alternatives. Industrial-scale electrification involves substantial investment and moves at a glacial pace compared to SaaS or consumer products.

Most limitations boil down to technical constraints, and many are caused by traditional battery solutions that lack the flexibility and transparency to support agile business processes and data-driven decision-making.

But the status quo is hanging on by a thread. It’ll take only one company to think outside the box to break the trance of “this is how things are done.” Will you be the leader or laggard?

So, what does customer-centric electrification look like, and how can you achieve the agility to create solutions that will put you ahead of the game?

But first… what people say they want does not necessarily provide the best user experience

So you ask your customers what they want and build it. End of story, right?

Not so fast.

Henry Ford once said, “If I had asked people what they wanted, they would have said faster horses." People didn’t say they wanted an iPhone or Tesla before these products became available because the concept didn’t yet exist in consumers’ frame of reference.

Innovation often happens when we leave the norm and common expectations behind. User’s acceptance of current solutions’ constraints doesn’t mean we should keep making incremental improvements based on the same limitations.

Being just a little better than the next guy may help improve your quarterly numbers. But a true paradigm shift requires changing assumptions.

What does a customer-centric user experience in electrification look like?

Let’s set aside what today’s technology can and cannot do and start from the user’s perspective. What should an electrification solution do for them?

Cost-efficient, flexible customization

Customers expect solutions to meet their requirements and integrate with existing processes. Fewer people are willing to go out of their way to accommodate a product’s constraints as customization has become a common feature in B2B and B2C products.

However, building one-of-a-kind solutions to satisfy each client’s requirements isn’t profitable. For example, product development and manufacturing costs can be unrealistically high if you design and manufacture multiple battery packs to accommodate different power input and output requirements or performance criteria.

Flexible and scalable technologies with a modular approach allow product builders to create solutions that meet evolving business and customer needs without changing production and fulfillment processes. Traditional battery solutions don’t allow such agility, and the first to enable customers to adjust parameters instead of changing their infrastructure will come out ahead.

Software-defined batteries (SDBs) built on the Tanktwo Battery Operating System (TBOS) make it possible to create one modular battery solution to adapt to various form factors and meet virtually any performance criteria by changing battery behaviors through software — allowing product builders to tailor their solutions cost-efficiently to meet customer demand.

User engagement and empowerment

The old-school way of giving customers a black box and saying, “Trust me, I’m an engineer,” no longer works as most people, especially B2B stakeholders, have hopped onto the data-driven decision-making bandwagon and demand data-driven insights.

Data analytics and transparency are good for business, and product builders should embrace data insights to empower and engage users. While hardware is a one-time purchase, analytics software and services offer recurring revenue opportunities. Using data to engage customers supports retention and provides long-term revenue opportunities.

The performance of electrified products and equipment is inevitably tied to the battery solution. But traditional ones can’t collect granular data, perform in-depth analytics (e.g., with AI and machine learning technologies), or ensure data privacy and security.

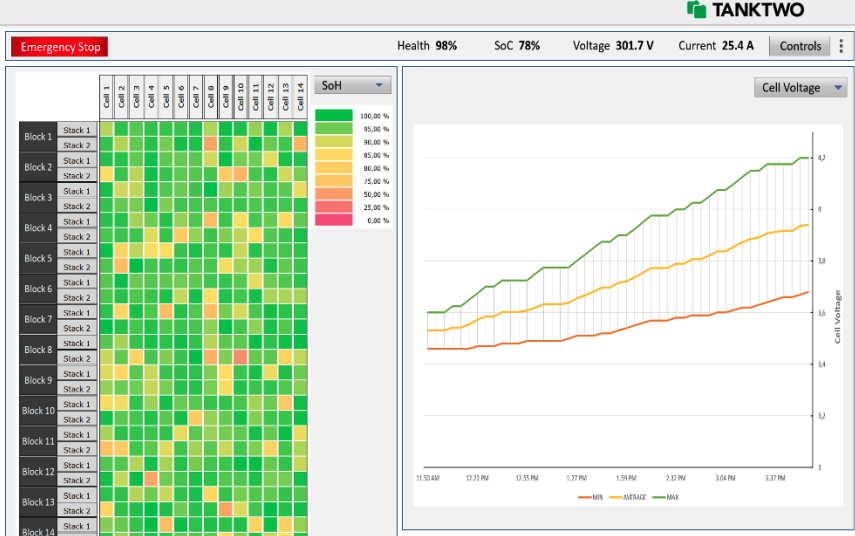

Our SDB solution makes it possible to harness dark data to tap into the power of data analytics and accelerate electrification. It also enables users to interact with the battery pack in real time to fine-tune parameters and adjust battery behaviors — creating a two-way dialog that aligns your product (and your brand) with the users’ interests.

Reliability, resiliency, and uptime

Your customers aren’t in the equipment repair and maintenance business. The more they can set it and forget it, the more likely they will select your product. A customer-centric solution means the customer doesn’t need to worry about the solution.

In the industrial sector, reliability and uptime are paramount. One broken piece of equipment in a long, complex, interdependent process can cause your customers headaches and trouble. Meanwhile, business resiliency is a top priority for executives. Besides reliability and redundancy, organizations need flexibility and adaptability for long-term success.

Traditional monolithic battery packs are often the weak link in the chain. One failed cell may require a wholesale replacement of the battery module or pack. Plus, non-standardized design and the inability to mix cells with different chemistries and ages create supply chain challenges that could take a piece of equipment out of commission for months.

Tanktwo’s SDB technology improves flexibility and agility to boost resiliency and reliability. For example, battery packs automatically rewire to bypass faulty cells to ensure continuous operations with consistent power output. Meanwhile, the modular design and ability to mix cells with different chemistries and ages streamline maintenance and repair.

Integration with organization-wide processes

Enterprise customers need to control who may access or use a piece of equipment in specific capacities to maintain governance and oversight. People can control access and usage of computer hardware and software applications, but such measures for physical industrial equipment are often clumsy and inadequate.

Most access control and security measures are tacked onto existing workflows and processes as afterthoughts. They’re costly, inefficient, and often insufficient for continuous monitoring and protection as security requirements shift.

Yet, security and governance are high-priority concerns for stakeholders and decision-makers. Without the appropriate measures, organizations can’t connect the dots between their physical equipment and digital infrastructure to drive innovation and support secure data collection, transfer, and analytics. Can you solve this challenge for your customers?

The answer could lie in the battery pack — equipment won’t work without power. Incorporating security and access control measures into existing workflows with our SDB solution enables granular control and oversight while ensuring secure data sharing among equipment and the rest of an organization’s digital infrastructure.

Develop customer-centric electrified equipment profitably

In the past, building custom battery solutions is costly and challenging. SDB built on TBOS allows product builders to adapt to changing customer requirements without bending over backward — spending millions on developing new technology or overhauling existing product design and production processes.

Book a Battery Technology Workshop to brainstorm how to differentiate your brand with customer-centric electrification solutions while keeping your processes streamlined and profitable.