[ TBOS TECH ] How We Achieve Flexibility: Any Cell Chemistry, Age, or Capacity is Fair Game

After the supply chain crisis in the past few years, most product manufacturers understand the risk of using components so unique that they can’t find a backup if one supplier fails to fulfill its order. Plus, the operating cost could skyrocket if the price of a particular cell type increases dramatically.

You can’t switch to other cell types to mitigate cost increases or respond to supply chain fluctuations if you deploy a battery solution that's limited to using cells of specific chemistry or capacity. Meanwhile, when you use one that requires cells with a similar level of deterioration, you’ll have to replace the entire pack even if just one cell has failed because you can’t put in one new cell.

TBOS makes these constraints history by allowing operators to mix old and new cells, different chemistries like lithium-ion and LFP, and cells of varying capacities and characteristics.

So how do we make the cells play nice together and meet various functional requirements?

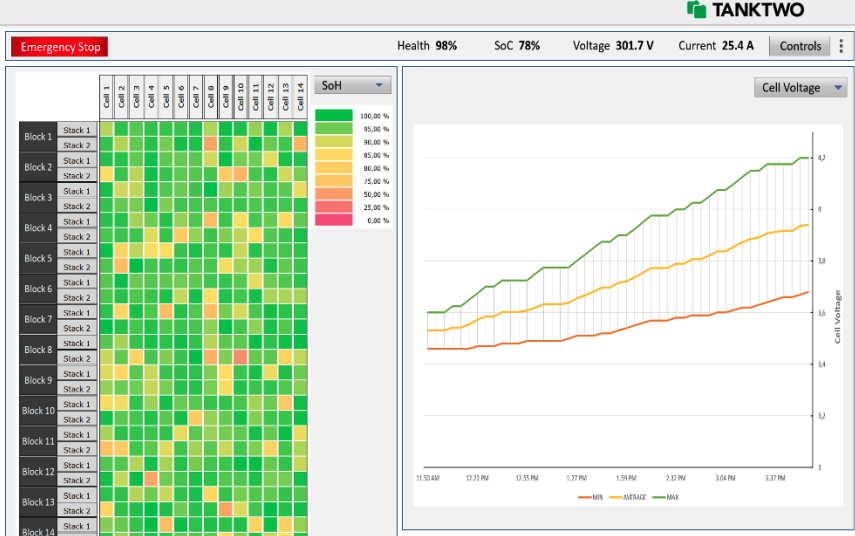

Our software allows operators to set parameters with a few clicks on the screen. Then, the algorithm takes care of the calculation and activates the most suitable cells to meet the set requirements.

The system performs continuous string re-selection, eliminating the need to balance cells during the charge/discharge cycle. It monitors each cell’s current continuously to ensure the string voltage stays within limits. If the string or cells fail to meet the requirements, the software automatically disconnects them, reselects the strings, and connects them again.

TBOS selects cells with the highest state of charge (SoC) for the string during discharging. If one cell has twice as much capacity as another, it’d be used two times more often during discharging.

This capability allows the system to compensate for the aging effect, so the battery pack doesn’t end up with a weak link that would necessitate replacement and cause it to be discarded simply because one cell has aged too quickly.

Even if you discover a weak link, you can easily replace only the broken cell(s) or module(s) without discarding the entire battery pack. This never-seen-before capability can help lower operating costs and eliminate downtime associated with waiting for replacement parts to arrive.